The Importance of Custom Manufacturing and Rapid Prototyping

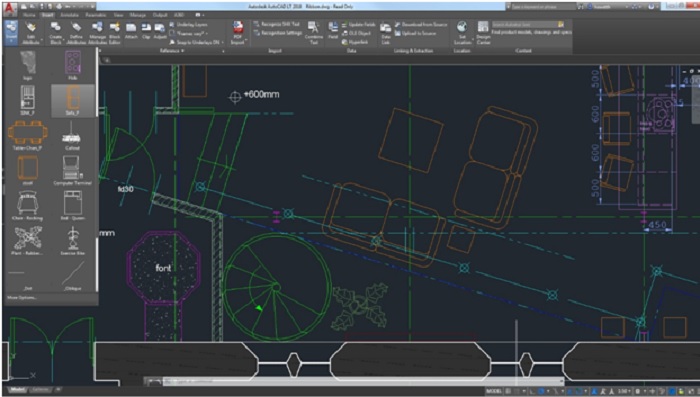

Manufacturing companies typically deal in creating items that are of an essential purpose for any given company. The process would normally involve, specification from the customer which would then be designed via a software created for this specific reason such as CAD (Computer-Aided Design), information about this can be found here. This software enables a designer or software engineer to produce any type of equipment from metal to plastic and even fiber. The result would be a technical vector-based drawing of a piece of equipment that would then be created in real life.

Using this software would mean very specific designs that include dimensions, specifications, tolerances, and processes to make it the best fit for when it will be produced into an object. Used mainly in industries that include automation, aerospace, architecture, shipbuilding, prosthetics to name a few, it is one of the most precise ways of designing something from concept to completion and bringing it to life.

Involved in this process are also stringent protocols to ensure the equipment is made to 100% capabilities and to the highest of standards, which is why this industry is so popular. Especially if your customer belongs to a specific and unique type of company, this would be the best service for them because they would not easily be able to find parts for their machinery elsewhere or it may be too costly for them to buy it in bulk.

In producing equipment that is tailor-made to a specific industry, custom manufacturing is of a highly significant position. Some produce a general item while others produce only the bespoke ones. from the smallest things such as screws and nails to the largest things such as machinery used in oil-rigs and machine industries, the custom industry can typically accommodate everything if they have the right tools. Once delivered according to specifications, then the idea of prototyping steps in. which we shall discuss later in this article, as the next stage.

Advantage of Custom Manufacturing

Lower Production Costs

A lot of companies have recently taken to this type of service mainly due to the cost-efficiency of it. It is much cheaper to get custom made items, not to mention your carbon footprint is less too than buying ready-made from shops and online stores. Besides, large and bulky orders are easily produced for half the price, due to no extra costs such as product packaging, shipping costs (if it’s local), and no name brand, just original good to use products.

It Is Flexible and Agile

When done correctly a unique product is designed and created for the end customer through this process, ensuring it meets their product specifications to the “T”. this means things can be chopped and changed at any time including the materials, design, and specifications. Even though they produce in bulk, the manufacturing companies make sure they are created to fit that industry and customer, and not mass-produced items that may or may not fit the mark.

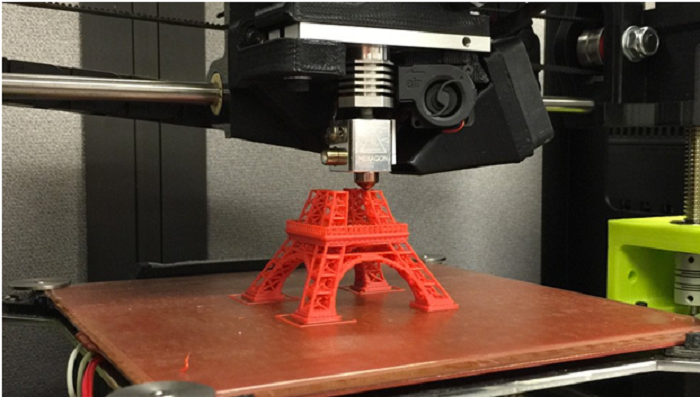

Custom Brand

This is a win-win service, for both the producers and the clients, as the latter gets to produce their brand and stick their preferred name on it. The offering for these types of services entails a value-added service. Using 3D printing technology, the possibilities are endless to the items that can be produced specifically for the user. When going for mass-produced items you are devoid of important elements such as finishing’s, engineering, and design assistance. There is also another angle to this service which involves deconstructing something, for instance when you want to understand the original structure of an object.

Examples of Custom Products

There can be a whole assortment of examples under this umbrella, and some of them include but are not limited to, medical devices and apparatus, aerospace components, architectural elements and components, military devices, to name a few.

In the end, it is a crucial option for those looking for their items unique specifications to be filled, which would normally not be able to be done by off-the-shelf components or products.

Rapid Prototyping

Although it describes a few different production technologies, the one used the most if RP (Rapid Prototyping) is an additive manufacturing process. This is a branch of the above custom elements. As the name suggests, it is comprised of a quick design process, and possibly the most important stage of any custom design. This includes the idea, the prototyping, and the testing of the model or quick turn machined parts and even the building of the 3Dimensional elements of it. Not many services offer this couple with their design and many companies fail at this. Finding one that offers this extra benefit is advantageous.

The computer-aided design, as mentioned above (CAD) software is responsible for this stage in the process and is typically accomplished by a skilled engineer and designer, coupled with a thorough knowledge of additive manufacturing also known as 3D printing using UV light (computer controlled), which brings products to life using a photosensitive liquid material, which turns solid within seconds upon application. It is the technology that is used to build the end-product using multiple layers of a specific material such as silicone or plastic, depending on the needs.

Two Types of Prototypes Available

Low-Fidelity: This category comprises of a model which has a clear distinction between the original and the final product.

High-Fidelity: When the design matches the projected product, this is known as high-fidelity. And is the most sought out kind of the two.

Are There Any Advantages?

The answer is simple, yes. And there is an array of advantages to this. Including in this list is the ability for the engineers to be able to see a clear view of the product development stages from the beginning to the production processes involved. If any adjustments or alterations need to be made it can happen easily in the early part of the development. Also, this is precise and cost-effective. Plus, there is no waste of materials either.

- 7 Key Web Design Principles To Create Impactful Web Experiences - June 20, 2024

- Why Your Small Business Needs SEO To Succeed - June 1, 2024

- Ultimate Guide to How Encoders Work: Types & Applications - June 1, 2024